Beacon Machine Manufacturing Co.,ltd

Blog

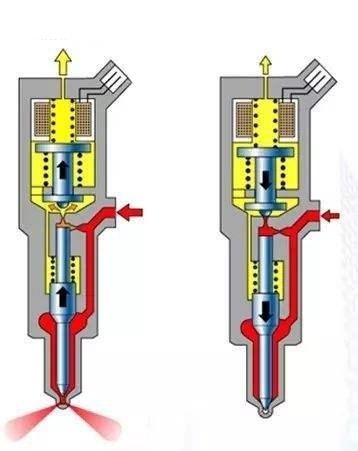

Makes it easy to understand how injectors work!

The oil injection process of the pump injector can be divided into two phases: pre-injection and main injection, and can also be divided into five processes: pre-injection, end of pre-injection, main injection, end of main injection and high pressure oil cavity feeding. The injection time and volume are controlled by the auxiliary plunger, needle valve, needle valve return spring, needle valve damper and electromagnetic control valve.

(1) Pre-injection. When the straight section of the cam contacts the rocker arm, the electronic control system supplies power to the electromagnetic control valve, causing the needle valve of the electromagnetic control valve to move to the left and cut off the channel between the high-pressure oil chamber and the low-pressure oil channel; at the same time, the oil pump plunger, under the action of the rocker arm, overcomes the elasticity of the return spring of the oil pump plunger to move downward, so that the oil pressure in the high-pressure oil chamber rises rapidly. When the oil pressure rises to 18MPa, the upward thrust generated by the fuel on the cone surface in the middle of the injection needle valve is greater than the preload of the return spring of the injection needle valve, and it will jack up the injection needle valve and start pre-injection.

(2) End of pre-injection. After the start of pre-injection, the injection needle valve continues to move upward, when the cam turns over 1/3 of the injection stroke, the lower end of the injection needle valve damper into the injection needle valve damper holes, the top of the injection needle valve can only be through a small gap in the fuel flow to the injection needle valve return spring chamber. In this way, the top of the injection needle valve formed a so-called “hydraulic washer”, preventing the injection needle valve to continue upward movement, so that the amount of fuel pre-injection is limited.

As the pump plunger continues to move downward, high-pressure oil chamber oil pressure continues to rise, when the oil pressure reaches the specified value, the auxiliary plunger in the high-pressure fuel downward movement, the volume of high-pressure oil chamber suddenly increased, the fuel pressure instantly decreased!

At this time, the upward thrust on the cone in the middle of the injection needle valve decreases, and the injection needle valve resets under the action of the injection needle valve return spring (due to compression by the auxiliary plunger and the elasticity increases), and the pre-injection ends.

(3) main oil injection pre-injection ends, the pump plunger continues to move downward, resulting in a rapid rise in oil pressure in the high-pressure oil chamber. When the oil pressure rises to greater than the pre-injection oil pressure (30MPa), the injection needle valve to move up, the main injection began. The oil pressure in the high-pressure oil chamber will continue to rise to about 205MPa because the oil pressure of the fuel in the high-pressure oil chamber rises extremely fast.

(4) End of main oil injection. When the electronic control system stops supplying power to the solenoid control valve, the solenoid control valve needle valve moves to the right under the action of the solenoid control needle valve return spring, connecting the high-pressure oil chamber with the low-pressure oil channel. At this time, the fuel in the high-pressure oil chamber through the electromagnetic control valve flow to the low-pressure oil channel, the fuel pressure in the high-pressure oil chamber drops, the injection needle valve in the injection needle valve return spring reset, the auxiliary plunger in the injection needle valve return spring closes the high-pressure oil chamber and the oil channel between the injection needle valve return spring, the end of the main injection.

(5) High-pressure oil chamber feeding. When the descending section of the cam contacts the rocker arm, the pump plunger moves upward under the action of the pump plunger return spring, and the high-pressure oil chamber generates a vacuum due to the increase in volume. At this time, the fuel in the low-pressure oil channel (connected to the inlet pipe) flows to the high-pressure oil chamber through the solenoid control valve until it fills the high-pressure oil chamber, thus preparing for the next injection.

Related products

Language

Language