Beacon Machine Manufacturing Co.,ltd

- Test Bench

- Balancing Machine

- Car Maintenance Equipment

- Other Hot Sale Test Bench

- Gasoline /Petrol Pump Test Bench

- Tester

- Ultrasonic Tank Cleaner

- Diesel Repair Tools

- Boring Grinding Machine

- Work Table

- For Bosch Parts

- For Denso Parts

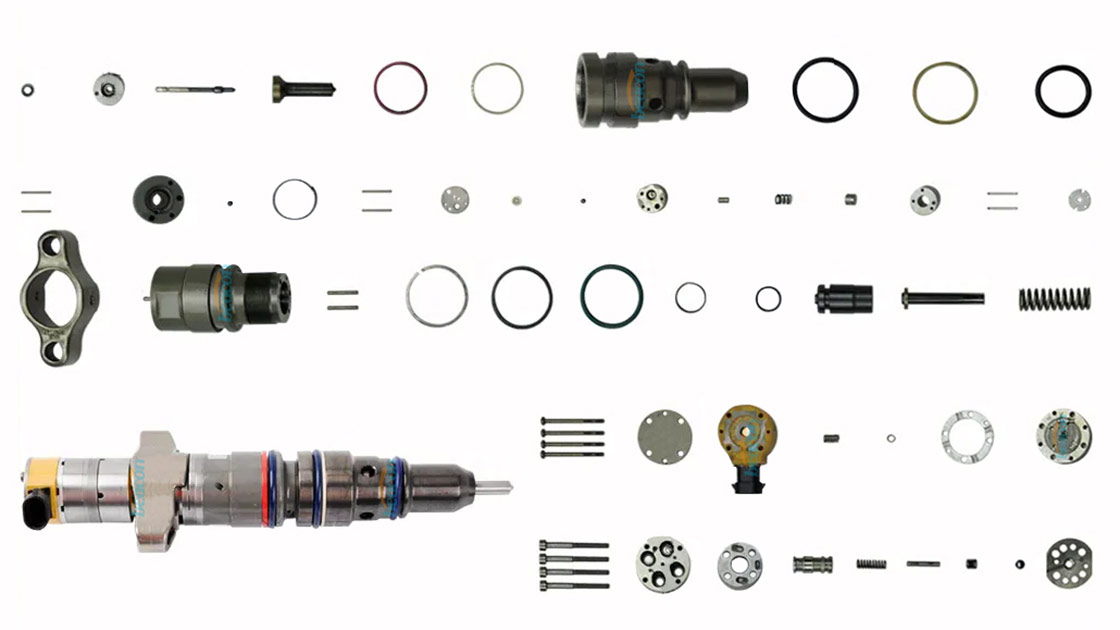

- For Cummins Parts

- For Siemens VDO Parts

- For Delphi Parts

- For CAT Parts

- Pipe Shrinking Machine

- Other Hot Sale Products

- EURO 2 Series Parts

- EUI EUP Series Parts

- FOR PT Parts

product details

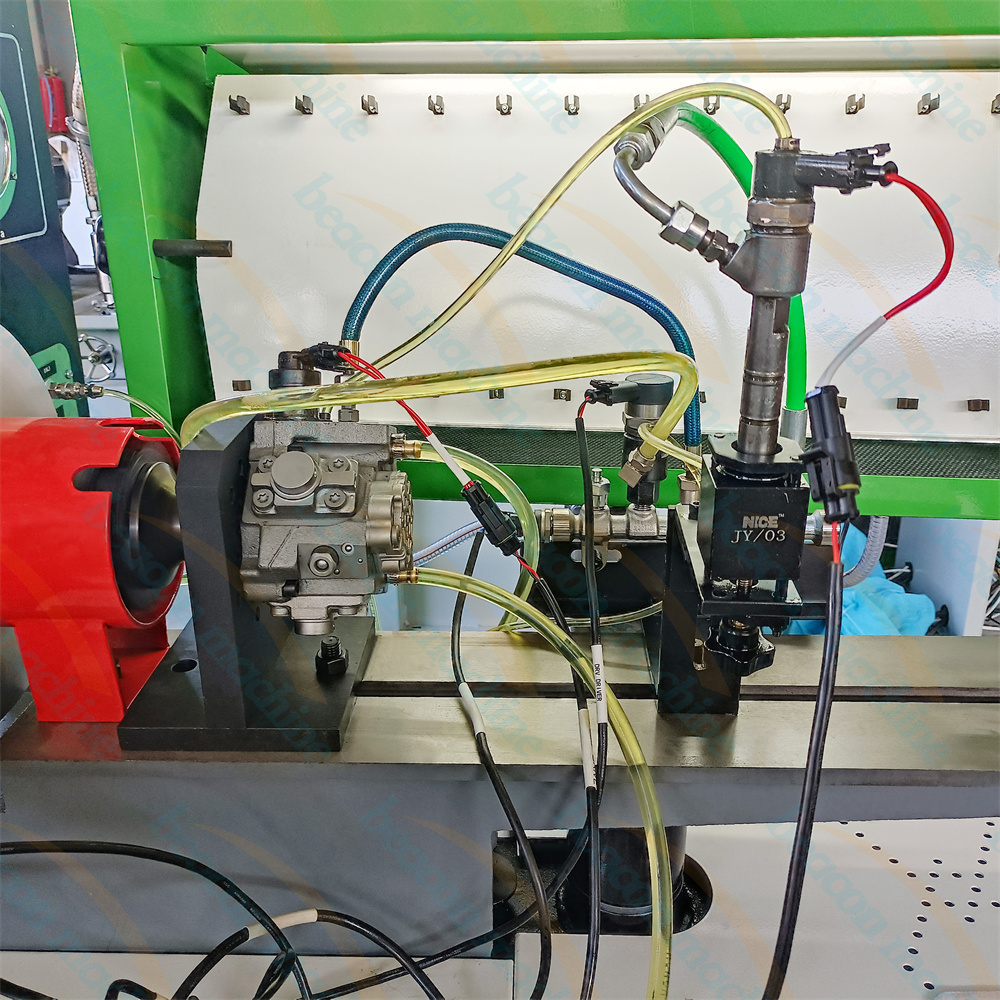

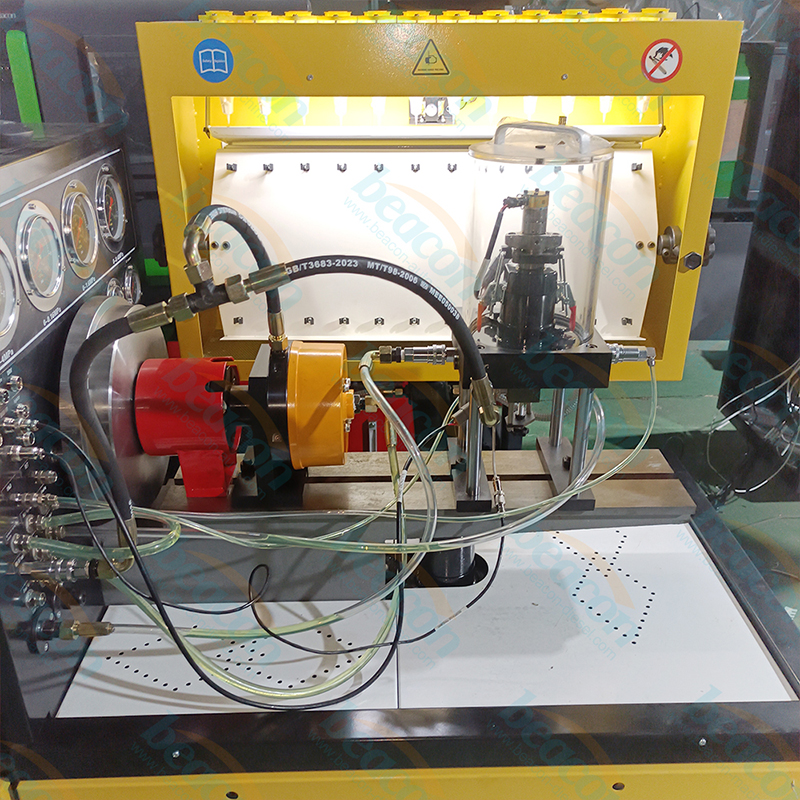

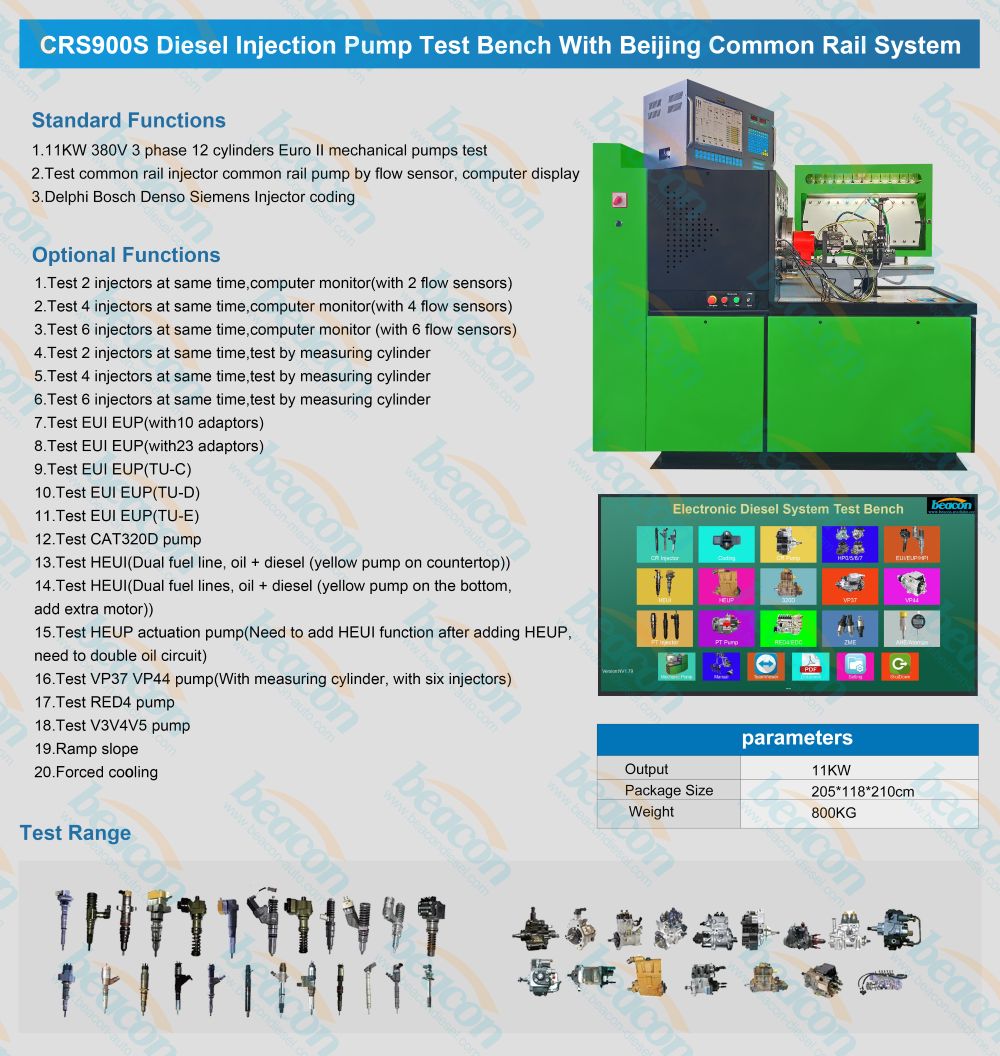

CRS900S Multifunction Diesel Injection Pump Test Bench

CRS900S Multifunction Test Bench can test mechnical pumps also can test common rail injectors and pumps with computer system

Introduction

CRS900S Multifunction Diesel Injection Pump Test Bench

CHARACTERISTICS :

1. Chaning frequency changing rotational speed

2. Low fall of rotational speed and high output torque

3. High measurement precision;

4. The functions of over voltage, overload and short circuit protection;

5. Ten classes Rotation speeds presetting;

6. Constant temperature controlled;

7. Ultra low noise;

8. Operating position: arbitrary side of the two work sides of the test stand;

9. Rotation speed, count, temperature, air pressure, advance angle and rack travel are measured and controlled by computers in real time, then displayed by 17″CRT or on request (17 LCD touch screen).

10. Built-in air resource;

11. All data can be made into reports and printed;

12. Automatically generating and displaying speed characteristics curve;( tooth bar stroke)

13. The data of the pumps can be saved, modified and obtained pump database;

14. It is very easy to find the data of the pumps in pumps database;

15. Windows operating system.

Main function:

1. Measurement of each cylinder delivery at any speed.

2. Test point and interval angle of oil supply of injection pump.

3. Checking and adjust the mechanical governor.

4. Checking and adjusting the distributor pump.

5. Experiment and adjusting of behavior of supercharging and compensatory device.

6. Measurement of oil return of distributing pump

7. Testing of the electromagnetic valve of distributor pump.(12V/24V)

8. Measurement of the internal pressure of distributor pump.

9. Checking of the advance angle of advance device.(on request)

10. Checking the sealing of injection pump body

11. Install tube of auto-sucking oil supply can check on oil supply pump(including VE pump.)

12. Checking the travel of stroke (on request)

10. Built-in air resource

parameter

Extra function :

(1) Integrated automatic operation, including test bench speed, rail rail pressure, flow measurement, report analysis, etc.,

one-button operation, the measurement results can be obtained.

(2) Test Bosch, Delphi, Denso, Siemens, Caterpillar, Cummins, solenoid valve or piezoelectric crystal injector, common rail high pressure pump.

(3) Can test Bosch, Caterpillar, Cummins, Delphi, and EUI and EUP, including Delphi E3 double solenoid valve EUI (optional);

(4) Test HEUI injector and actuating pump (optional);

(5) Test Caterpillar 320D high pressure pump (optional);

(6) Test VP37,VP44,RED4,Denso V3/V4/V5 pump (optional);

(7) Test Cummins HPI injector,PT pump (optiona);

(8) The test standard data is consistent with the original data, and the test accuracy reaches the original factory standard;

(9) The database is fully open, the part number can be increased.

(10) Automatic network upgrade, test data and functions are kept up to date;

(11) The injection response time can be tested;

(12) The fuel injector compensation code can be generated;

(13) Test injector resistance and indctance

other products

Our factory

Related products

Language

Language