Beacon Machine Manufacturing Co.,ltd

- Test Bench

- Balancing Machine

- Car Maintenance Equipment

- Other Hot Sale Test Bench

- Gasoline /Petrol Pump Test Bench

- Tester

- Ultrasonic Tank Cleaner

- Diesel Repair Tools

- Boring Grinding Machine

- Work Table

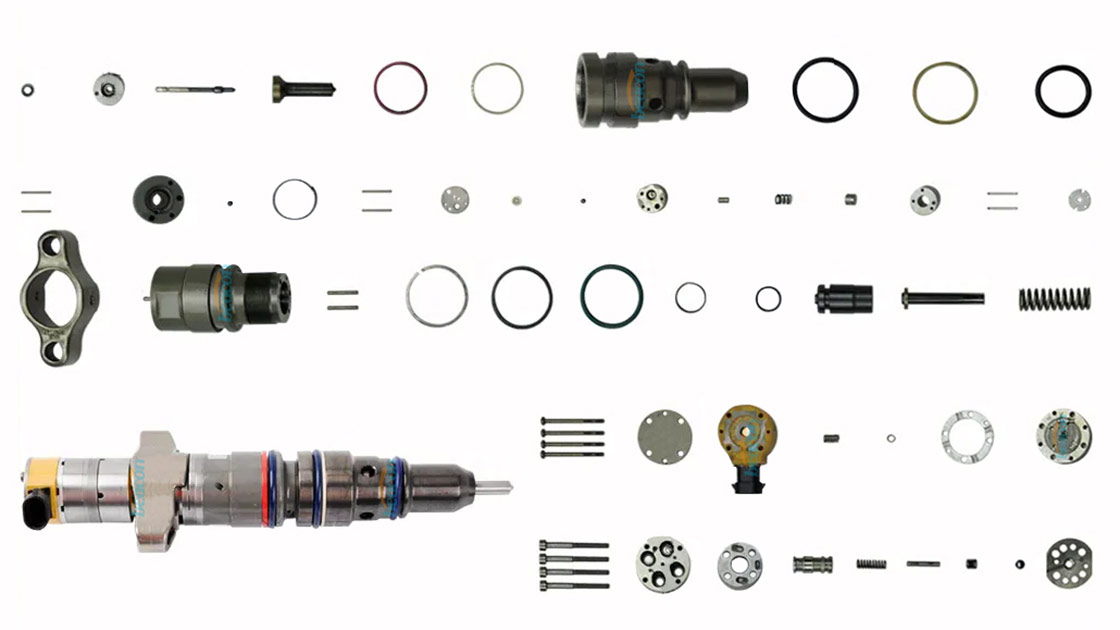

- For Bosch Parts

- For Denso Parts

- For Cummins Parts

- For Siemens VDO Parts

- For Delphi Parts

- For CAT Parts

- Pipe Shrinking Machine

- Other Hot Sale Products

- EURO 2 Series Parts

- EUI EUP Series Parts

- FOR PT Parts

product details

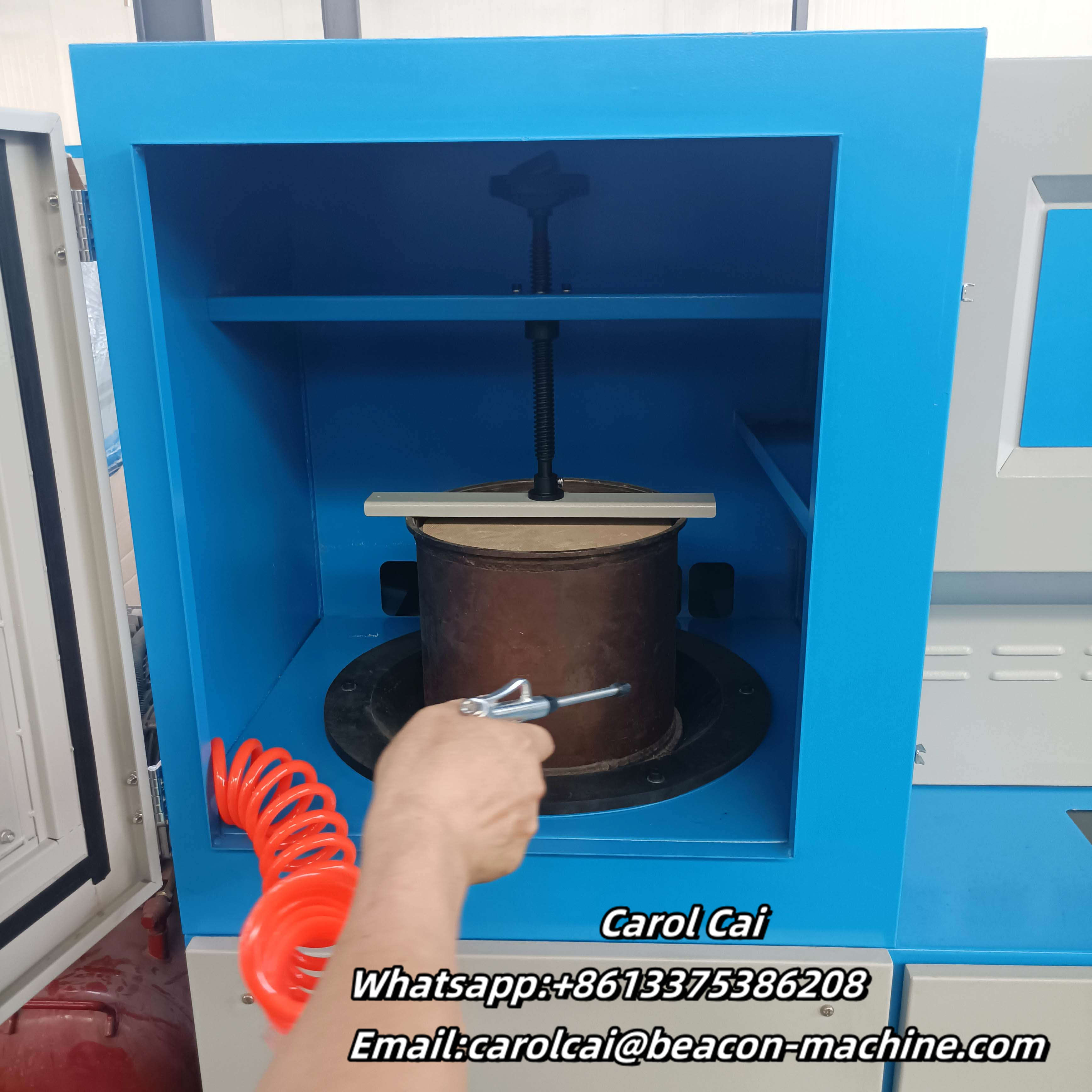

DPF-BLB Car Workshop Machine DPF Filter Cleaner Diesel Particulate Filter DPF regeneration equipment Cleaning Equipment

The DPF regeneration equipment is a device that reduces particulate matter PM in the exhaust gas by filtering and capturing particulate matter. It is a device that emits first and then collects.

Introduction

DPF-BLB Car Workshop Machine DPF Filter Cleaner Diesel Particulate Filter DPF regeneration equipment Cleaning Equipment

Use external energy to increase the temperature in the trap to ignite and burn the particles. When the temperature in the trap reaches 550℃, the deposited particles will oxidize and burn. If the temperature does not reach 550℃, too much sediment will block the trap. At this time, it is necessary to use external energy (such as electric heaters, burners or changes in engine operating conditions) to increase the temperature in the DPF to oxidize and burn the particles.

DPF passive regeneration: Use fuel additives or catalysts to reduce the ignition temperature of particles so that the particles can ignite and burn at normal diesel engine exhaust temperature. Additives (cerium, iron and strontium) should be added to the fuel in a certain proportion. Too much additives will affect the life of the DOC, but too little will cause regeneration delay or increase in regeneration temperature.When both active and passive regeneration of the vehicle cannot be achieved, active regeneration is required.

parameter

other products

Our factory

Related products

Language

Language