Beacon Machine Manufacturing Co.,ltd

- Test Bench

- Balancing Machine

- Car Maintenance Equipment

- Other Hot Sale Test Bench

- Gasoline /Petrol Pump Test Bench

- Tester

- Ultrasonic Tank Cleaner

- Diesel Repair Tools

- Boring Grinding Machine

- Work Table

- For Bosch Parts

- For Denso Parts

- For Cummins Parts

- For Siemens VDO Parts

- For Delphi Parts

- For CAT Parts

- Pipe Shrinking Machine

- Other Hot Sale Products

- EURO 2 Series Parts

- EUI EUP Series Parts

- FOR PT Parts

product details

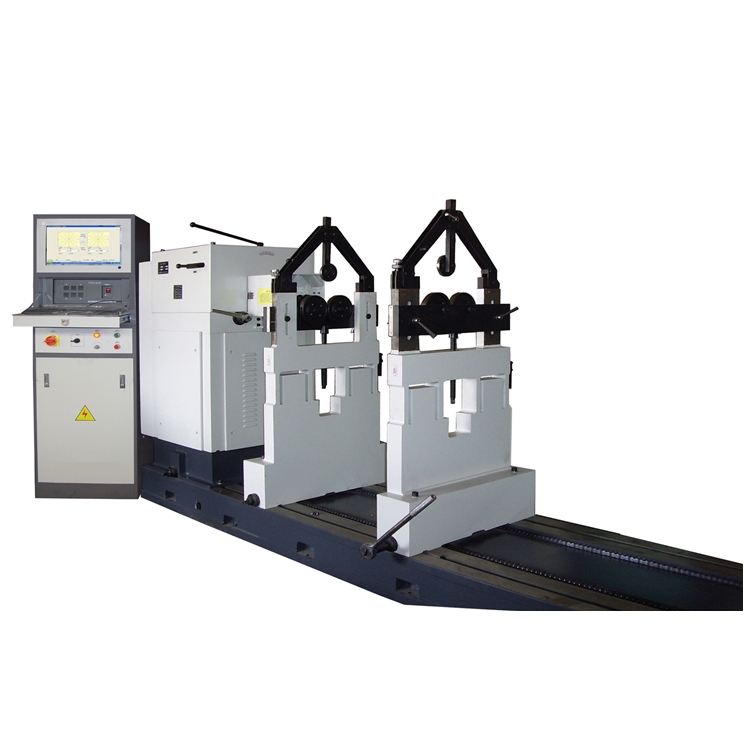

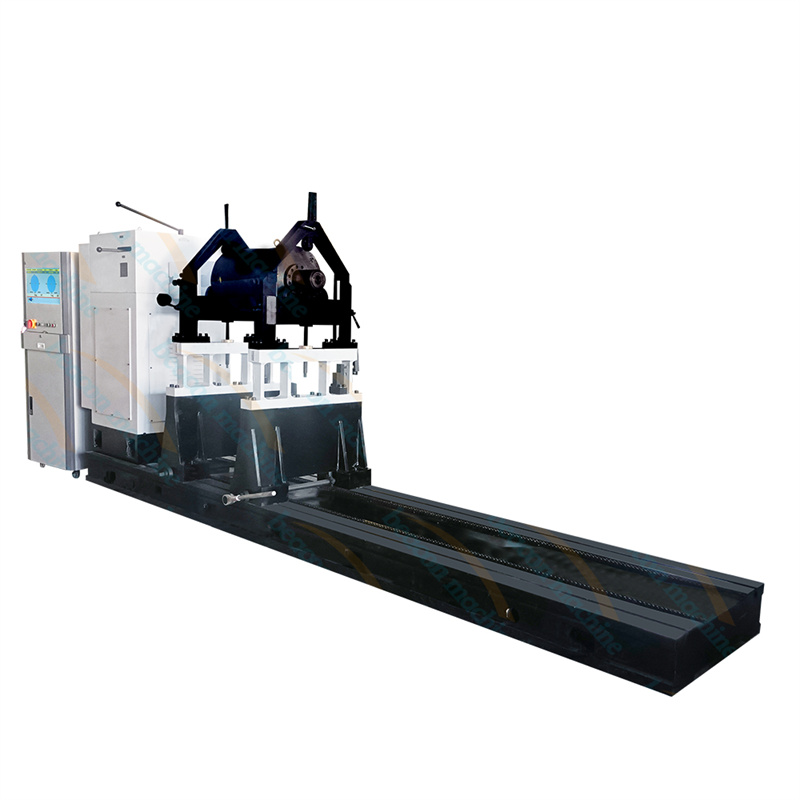

YLSD-200 Double-Sided Vertical Dynamic Balancing Machine

YLSD-200 running under the windows XP operating system, the software mainly completes the dynamic balance measurement, and records storage statistics and printing.

Introduction

YLSD-200 Double-Sided Vertical Dynamic Balancing Machine

1.Function and overview

The upper computer uses a 15-inch touch screen all-in-one computer, running under the windows XP operating system, the software mainly completes the dynamic balance measurement, and records storage statistics and printing. The measurement data can be downloaded via U disk at any time.

The system adopts the single-station structure of the structural base, with optional selection of balance measurement and de-weighting. The whole machine adapts to dusty environment, integrated structure, mechanical part safety protection, the overall structure of the equipment is centralized, and it is convenient to use.

1) A set of 15-inch Advantech touch screen all-in-one machine, a set of balance measurement system, and the electronic control part are located on the side of the operating station.

2) The impeller is under isolation protection during the rotation test. The upper and lower doors are protected by pneumatically movable doors. The upper and lower doors are full perspective windows to observe the rotation of the impeller. The perspective windows have the ability to protect the impeller from breaking. The upper plane of the operating position is about 800mm from the ground. .

3) The interface sets the unbalance qualified value, any unbalance exceeding the limit will be judged as unqualified, and the interface displays the corrected grams at the correction radius.

4) Automatically record and store the measurement results for each measurement. The storage records include the following information: work order number, date, time, fixture compensation status, rotor file number, static unbalance and angle, even unbalance, static unbalance critical value, whether Qualified, operating personnel, etc.

5) The device has an angle tracking function. After the measurement is completed, there is no need to manually find the corresponding angle of the mechanical dial with the naked eye.

6) The equipment can be equipped with automatic positioning function. After the measurement is completed, the workpiece is automatically positioned at the calibration stop at the calibration position.

Measurement workflow:

Place the workpiece manually—lock the workpiece—close the protective door—start the motor—measured—stop the motor, and the display shows the unbalance and angle value (automatically record and store)—open the protective door—manual correction—recheck— Manually remove the workpiece.

parameter

Power supply voltage: three-phase four-wire, 380V±10%. Single phase 220 V±10% 50Hz

Compressed air: 0.4-0.6MPa

Environment temperature: -5℃~40℃

Environmental humidity: 85% (maximum)

Overhanging height of workshop: 8 m

product video

other products

Our factory

Language

Language