Beacon Machine Manufacturing Co.,ltd

Blog

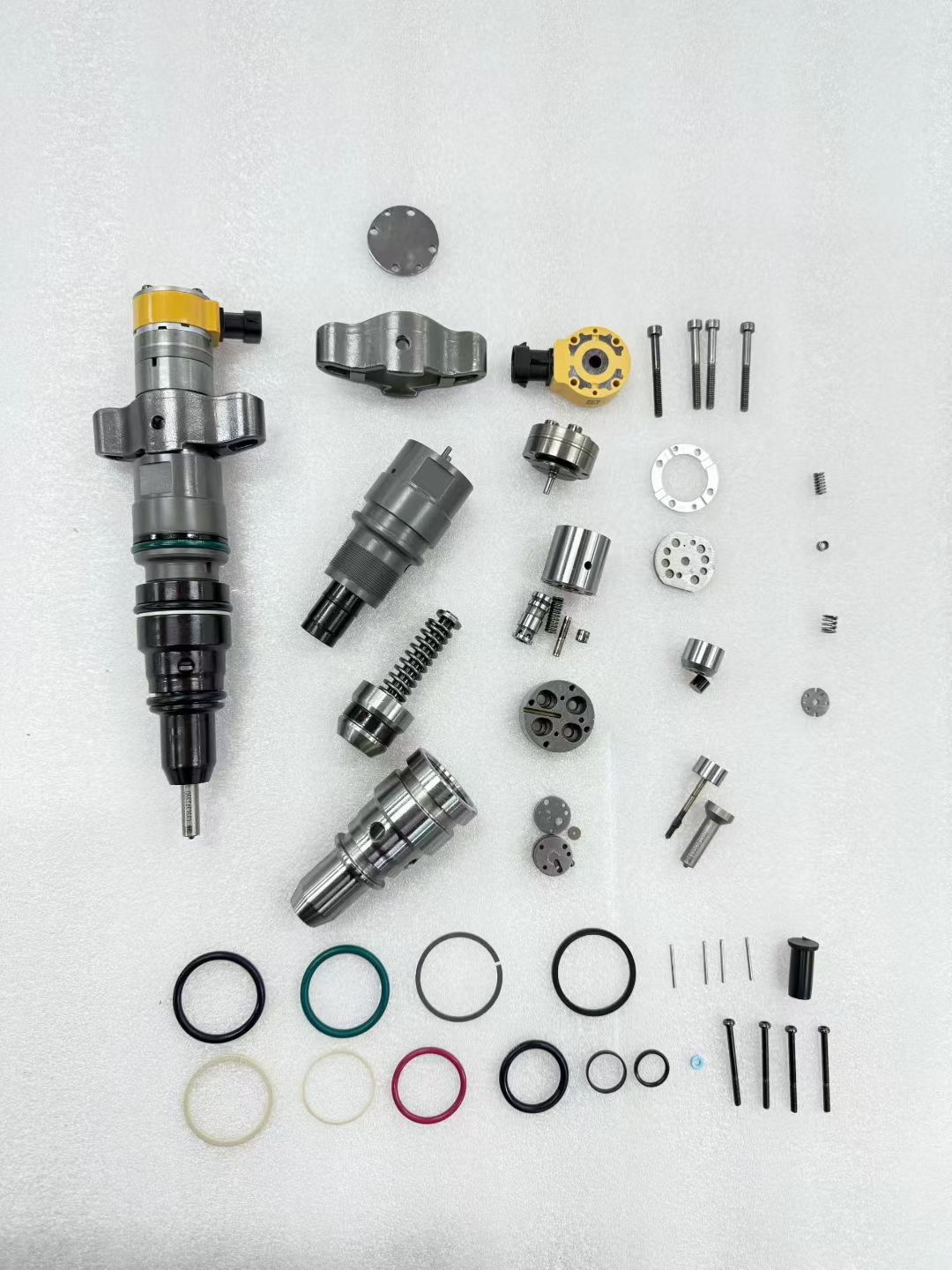

Caterpillar C9 Actuator Pump Fault Analysis

Caterpillar C9 Actuator Pump Fault Analysis

The Caterpillar C9 engine uses a HEUI (Hydraulic Actuated Electronic Unit Injection) fuel system. Failures in its actuation pump (HEUI pump) are typically related to insufficient oil pressure, oil contamination, internal wear, and control valve malfunctions. Here is a detailed breakdown of these faults:

Common Fault Symptoms

Reduced Engine Power/Insufficient Power: The most common symptom, especially with increased load or engine temperature.

Difficulty Starting or Failure to Start: Particularly noticeable in low temperatures due to insufficient actuation oil pressure required for starting.

Engine Vibration, Unstable Idle Speed: Caused by inconsistent fuel delivery.

Abnormal Exhaust Smoke: May produce black smoke (over-fueling) or white smoke (unburned fuel).

Abnormally Low Oil Pressure: Damaged internal seals in the actuation pump may cause oil leakage into the fuel system or elsewhere.

Fault Codes: The ECM (Engine Control Module) may record fault codes related to the injection actuation pressure control valve (IAPCV) or pressure sensor.

Engine Knocking or Unusual Noises: May be due to insufficient lubrication or wear of internal components caused by low oil pressure.

Fault Cause Analysis

* **Oil Contamination and Inappropriate Viscosity:**

**Cause:** The C9 actuator pump uses engine oil as its power source. If the oil is dirty or its viscosity is not up to standard, contaminants will wear down the pump's internal components, leading to performance degradation.

**Consequence:** Wear causes internal leakage, preventing the actuator pressure from reaching the required level.

* **Internal Component Wear:**

**Cause:** Over time, the pump's plungers, pistons, valves, and seals will naturally wear down.

**Consequence:** Unstable pressure control and increased internal leakage.

* **Oil Pressure Regulating/Control Valve (IAPCV) Fault:**

**Cause:** The IAPCV is responsible for regulating and controlling the actuator oil pressure. A stuck valve core, wear, or electrical faults (short circuit, open circuit) will affect its normal operation.

**Consequence:** Actuation pressure that is too high or too low leads to abnormal oil supply.

* **Oil Passage Blockage:**

**Cause:** A clogged oil filter or debris in the oil passages restricts oil flow to the actuator pump.

**Consequence:** The pump cannot receive sufficient oil, resulting in insufficient pressure.

Injector Internal Leakage:

Cause: Although the fault is downstream of the pump, severe internal leakage in one or more injectors can prevent the entire actuation system from building pressure, thus manifesting as an actuation pump failure.

Consequence: Engine fails to start or experiences severe power loss.

Mounting Surface Deformation or Seal Damage:

Cause: Damaged seals between the actuation pump and the engine mounting surface, or uneven mounting surfaces.

Consequence: Oil sprays out, oil level drops rapidly, and system pressure is lost.

Troubleshooting and Repair

Using Diagnostic Tools: Use professional diagnostic instruments such as Caterpillar Electronic Technician (Cat ET) to read fault codes and monitor the difference between the actual actuation pressure and the target pressure.

Check Oil Condition: Ensure the use of oil with the correct viscosity and cleanliness, and change the oil and filter on schedule.

Pressure Test: Connect a high-pressure gauge to test the actual output pressure of the actuation pump. Low pressure usually indicates a serious leak inside the pump or in the system.

Check IAPCV Circuit: Check the IAPCV control valve and its wiring harness connections to rule out electrical faults. System flushing: If the pump experiences a serious malfunction (e.g., producing metal shavings), the high-pressure oil passages and the entire oil system must be thoroughly flushed to prevent the new pump from failing again.

Timely diagnosis and maintenance are crucial for ensuring the reliable operation of the C9 engine.

Related products

Language

Language