Beacon Machine Manufacturing Co.,ltd

CATEGORIES

- Test Bench

- Balancing Machine

- Car Maintenance Equipment

- Other Hot Sale Test Bench

- Gasoline /Petrol Pump Test Bench

- Tester

- Ultrasonic Tank Cleaner

- Diesel Repair Tools

- Boring Grinding Machine

- Work Table

- For Bosch Parts

- For Denso Parts

- For Cummins Parts

- For Siemens VDO Parts

- For Delphi Parts

- For CAT Parts

- Pipe Shrinking Machine

- Other Hot Sale Products

- EURO 2 Series Parts

- EUI EUP Series Parts

- FOR PT Parts

product details

Diagnostic tools CR309 BIP common rail diesel injector testing machine

CR309 injector calibration machine for Bosch Denso Delphi Siemens Cummins CAT common rail and piezo injectors test with BIP and electronic flap measuring cylinder

Introduction

Diagnostic tools CR309 BIP common rail diesel injector testing machine

Function

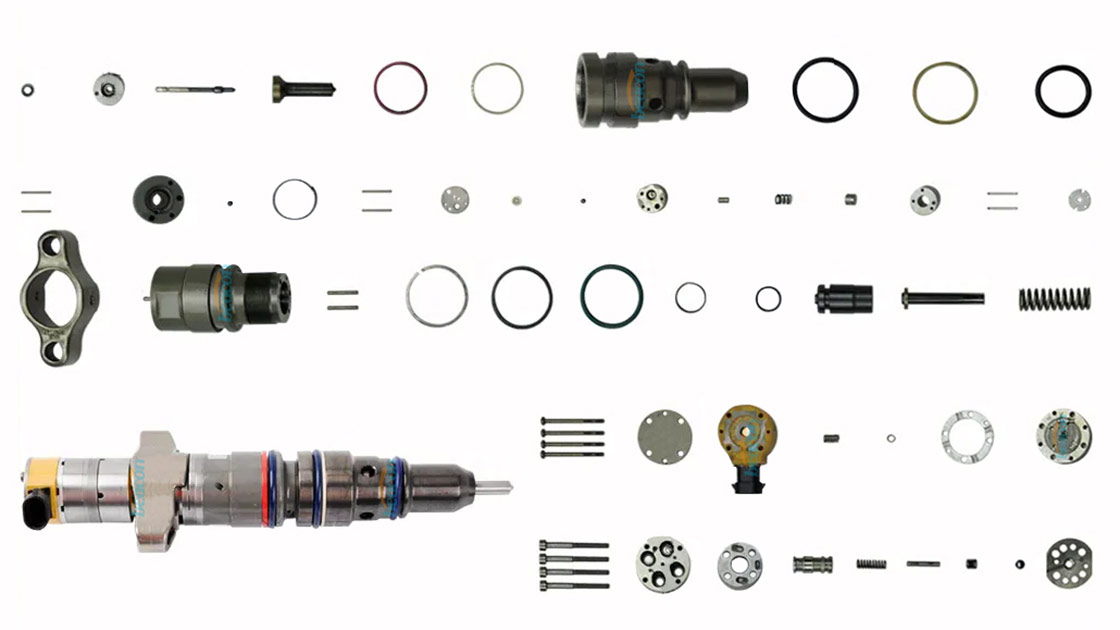

1.Test the common rail injector2.Test the piezo injector

3.Delphi, Denso, Bosch, Siemens coding function

4.BIP function

5.Graduated cylinder test injector with electronic flap

Optional features

1.AHE injector dynamic stroke (with Bosch 110, 120 stroke measuring tool + dial gauge)

2.Rail pressure sensor test

3.DRV/HPV test

4.Solenoid valve test

5.Bosch 4 pins injector test

6.Simultaneously measure 4 injectors with 4 flow sensors

(Modify the system + add 3 additional flow sensors + 3 high-pressure oil pipes + 6 solenoid valves + 6 filter elements + 3 filters + 1 four injector fixtures)

7.Simultaneously measure 2 injectors with 2 flow sensors

(Modify the system + add 1 additional flow sensor + 1 high-pressure oil pipe + 2 solenoid valves + 2 filter elements + 1 filter + 1 double injector fixture)

parameter

1.The operating environment, conditions and specifications of the rail injector test bench

Temperature (during operation) :-10~50℃ (14~122°F)

Temperature (non-operating) :-20~70 ℃ (-4~158°F)

Relative humidity (during operation):15%~95% at 40 ℃ (no condensation)

Relative humidity (non-operating):90% at 65 ℃ (non-condensing)

2.Technical parameters

Nominal power of main engine (kW): 4

Heating tube power (kW): 1

Nominal power of circulating pump (kW): 0.18

Power supply voltage: 220V/380V

Solenoid valve drive current: 0-30A

Frequency: 50Hz/60Hz

Main motor power: 4KW

Oil temperature control method: heater and forced circulation air cooling system

Temperature control range: 40±2℃

Use environment temperature: <35℃

Maximum pressure of high pressure system: 250Mpa

Common rail pump: Bosch CP3.3

Pressure control range: 0-2500Bar

Injector injection duration: 100-5000µs

Motor speed range: 0-2000rpm

Flow measurement range: 0-4000ml/min

Noise level: <75dB

Test mailbox volume: 40L

Net weight/Gross weight: 300/360KG

Appearance net size: 1460*970*1610MM

Wooden box size after packaging: 1710*1130*1750MM

Fuel tank computer: two-way display of measuring cylinder

Temperature (during operation) :-10~50℃ (14~122°F)

Temperature (non-operating) :-20~70 ℃ (-4~158°F)

Relative humidity (during operation):15%~95% at 40 ℃ (no condensation)

Relative humidity (non-operating):90% at 65 ℃ (non-condensing)

2.Technical parameters

Nominal power of main engine (kW): 4

Heating tube power (kW): 1

Nominal power of circulating pump (kW): 0.18

Power supply voltage: 220V/380V

Solenoid valve drive current: 0-30A

Frequency: 50Hz/60Hz

Main motor power: 4KW

Oil temperature control method: heater and forced circulation air cooling system

Temperature control range: 40±2℃

Use environment temperature: <35℃

Maximum pressure of high pressure system: 250Mpa

Common rail pump: Bosch CP3.3

Pressure control range: 0-2500Bar

Injector injection duration: 100-5000µs

Motor speed range: 0-2000rpm

Flow measurement range: 0-4000ml/min

Noise level: <75dB

Test mailbox volume: 40L

Net weight/Gross weight: 300/360KG

Appearance net size: 1460*970*1610MM

Wooden box size after packaging: 1710*1130*1750MM

Fuel tank computer: two-way display of measuring cylinder

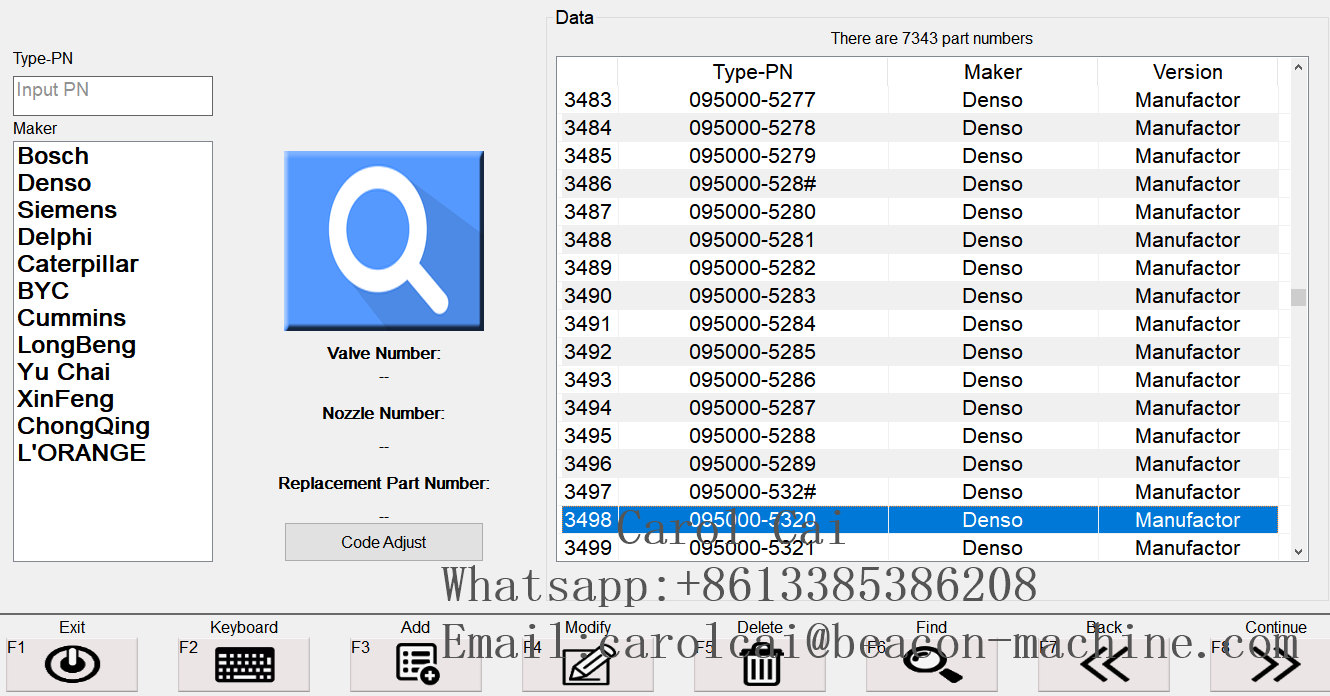

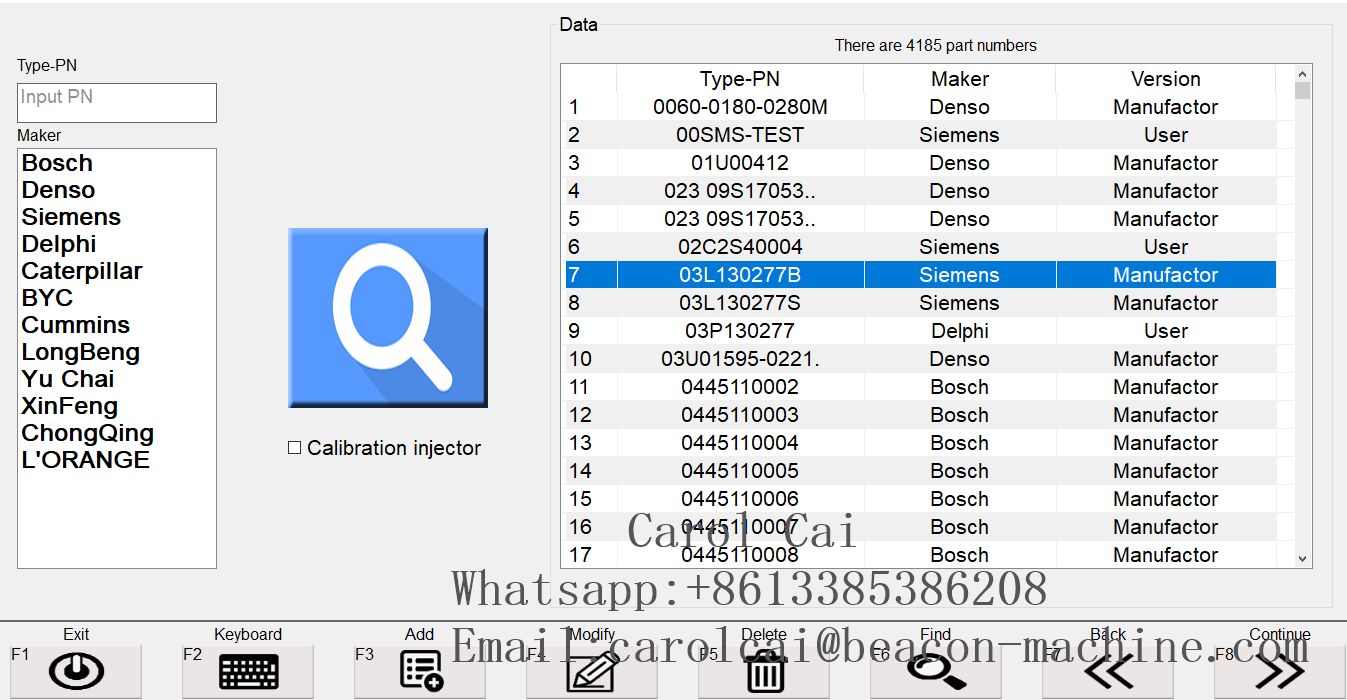

Lastest system,support online upgrade and remote.

1.More than 7000 types injector data

2.More than 4000 types injector coding data

other products

Our factory

Related products

Language

Language